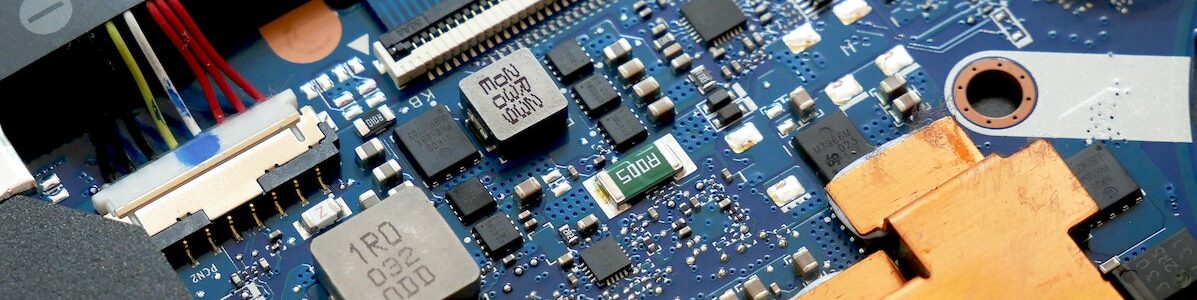

Board-to-board interconnect systems play an important role in many applications, because they provide signal connections between two printed circuit boards. There are different types of board-to-board connectors that are widely used in manufacturing. Continue reading to discover the different types, including flexible interconnect systems, and their uses in a range of applications.

What is a board-to-board connector?

Board-to-board connectors provide a reliable connection between printed circuit boards (PCBs), without the use of wires or cables. The connection can be a permanent one with hard soldering, which is a process of soldering a pin header at both ends of the PCBs. This approach can be used in a solution where no mating cycles are required.

Most applications require the printed circuit boards to be connected and disconnected to simplify the assembly process and allow design flexibility. This allows PCBs to be easily replaced and upgraded.

Despite being available in many configurations, board-to-board connectors operate on a basic male to female connection of pins to sockets. This can be described as a ‘mating cycle’.

Types of board-to-board interconnect systems

Typically, there are two types of board-to-board interconnect systems, and they are:

- Flexible Interconnect Systems

- Rigid Interconnect Systems

Advantages of flexible interconnect systems

There are a wide range of advantages to using a flexible interconnect system, and they are:

- Can be integrated into multiple PCBs in a panel, which can be broken out and folded into position.

- Can be used to connect PCBs over a longer distance than is possible with a rigid system.

- Can be used in complex geometries (connecting PCBs that are not aligned).

- Can be used for signal and power applications up to 12 amps per conductor.

- Excellent for use when the PCBs are subjected to vibration.

- Available in through-hole or SMD packages for automatic pick and place or reflow soldering.

Advantages of rigid interconnect systems

There are also a variety of advantages when using a rigid interconnect system too.

- Can offer multiple connection points for transferring signal and power between multiple PCBs.

- Can be used for mechanical as well as electrical board connectors.

- Ideal when PCBs are stacked on top of each other.

- Can be supplied in ultra-fine pitches and multiple rows giving a large number of connection points in a dense footprint.

- Operate over short distances and are pluggable using a male and female setup.

- Offered in conventional through hole format for manual insertion and SMD options for automatic pick and place, and reflow soldering.

- Can be assembled separately before PCBs are plugged together.

- Allow a modular approach, enabling you to add optional daughter boards.

- Can be supplied with gold plated contacts for low signal transfer.

Which applications use board-to-board connectors?

Board-to-board interconnect systems are typically used in the following applications:

- Industrial control systems

- Energy metering

- Automotive electronics

- White goods

Board-to-board connectors can be used on high-speed trains and industrial controls, data centre storage and switching systems. These electrical board connectors provide reliable high-speed data transmission with greater clarity. They can also boast flame-retardant polarised housings that protect connections in harsh environments.

In high-speed computing, board-to-board connectors provide a support system to data centre architectures and rugged embedded computing systems.

Board-to-board interconnect systems at Hitaltech

At Hitaltech, we offer a wide range of board-to-board connectors to suit any application.

We offer a range of flat flexible cables that can be used in places where electrical connections require a high flexibility and/or PCBs to be connected, that are subject to vibrations. Available typically from 2 to 32 poles, these flat flexible cables are available with different insulation materials. Depending on the application, these cables can be supplied in materials that can withstand reflow soldering temperatures.

Our Conex-It rigid interconnect systems are typically used where PCBs need to be stacked on top of each other or side by side. With either permanent or plug-in connection methods, our rigid range offers a wide variety of available options with various combinations of length, pin pitches, surface mount, through hole, plating types, orientations and number of poles.

Despite the vast range, customisation options mean there’s always a connector for every application.

For more information, contact Hitaltech today on 01253 899910, or email us at uksales@hitaltech.co.uk.