When it comes to connecting printed circuit boards (PCBs), there are two main types of connectors: rigid connectors and flexible connectors. But what’s the difference and when might you choose one type of connector over the other? Hitaltech explains the functions and benefits of our market-leading Conex-it range of rigid and flexible connectors.

Rigid Connectors

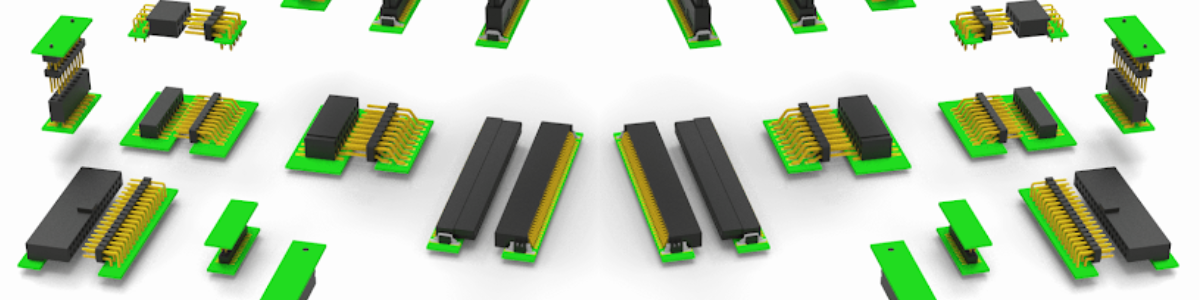

Our Conex-It rigid interconnects are typically used where PCBs need to be stacked on top of each other or side by side. Available with either permanent or plug-in connection methods, our rigid range offers a wide array of options. These include various combinations of length, pin pitches, surface mount, through hole, plating types, orientations and number of poles. You name it, Hitaltech is sure to have the ideal rigid connector for the job.

We introduced our range of rigid connectors in 2019 to give our customers even greater choice and supply simplicity. All whilst maintaining the quality, availability and speed of delivery that has become the hallmark of Hitaltech. We’ve sourced the largest possible range of rigid connectors available. As such, we can provide tens of thousands of permutations, so you can be sure there’s always a product to meet your needs.

Flexible Connectors

Our range of flat, flexible cables that are suitable for electrical connections needing high flexibility or for connecting PCBs that are routinely subject to vibrations. These highly flexible cables can either be soldered at each end directly onto the PCB for a permanent connection or they can be supplied with a connector on either end. Thus providing a flexible connection solution – in every sense of the word.

Available typically from two to 32 poles, our flat, flexible connectors are available in a variety of different insulation materials. Depending on the application, these cables can also be supplied in materials that are designed to withstand reflow soldering temperatures. Typical applications for flexible interconnects include industrial control systems, energy metering, automotive electronics and white goods to name but a few.

So what is the difference?

As we’ve seen from the descriptions above, the main difference between rigid connectors and flexible connectors is in their application. Rigid connectors are the natural choice for stacking PCBs on top of one another or at right angles. However, for a greater degree of flexibility, both in terms of high-flex connections and either permanent or hot-swap configurability, flexible connectors offer a versatile alternative.

Contact Hitaltech today

Hitaltech has been creating high-quality connecting technologies and enclosures for electronic and electrical applications for over 35 years. Our vast range of superior products has been designed with our customers in mind. If you are looking for professional connecting technologies and enclosures, we have everything from wire-to-board connectors to hand held enclosures available to suit your specific application requirements.

If you would like to find out more about our products, including our connecting technologies and enclosures, please contact us today on +44 (0)1253 899910 or email uksales@hitaltech.co.uk. The Hitaltech team is always on hand to answer any questions you may have.