As design engineers are pushed by marketing to design an aesthetically pleasing product which can be differentiated from the competition, they are increasingly facing a situation where a standard, off the shelf electronic enclosure no longer meets their requirements.

The Challenge

In large volume products, a custom plastic enclosure will be realised through the design and production of a custom mould tool with a pay back of the cost being realised in a relatively short timescale. However, in low to medium volume products, the options to invest in the necessary mould tools for a custom electronic enclosure is neither practical nor financially viable. As a result, a degree of customisation of a standard off the shelf enclosure is often required through machining, drilling and/or printing. This process is usually carried out by a third party, leading to a substantial hike in costs, longer lead times and there are often large minimum order quantities. The customisation process can be carried out internally through investment in machining and printing equipment, however this can require substantial allocation of internal resources.

Hitaltech currently supply DIN Rail mounting enclosures, hand held and wall mounting enclosures into the building automation market. Within this market both energy management technologies and light management are registering a high growth rate and as a result, manufacturers within this industry are striving to design a product which can be differentiated from the competition on both a functional and aesthetical level. As a result, a trend has emerged over recent years where a growing number of Hitaltech’s existing customers within this market are finding themselves in a trade off situation between customisation costs and the need to set themselves apart from their competitors.

The Solution

In order to meet this need, Hitaltech and their manufacturing partner Italtronic have worked together to offer a range of DIN Rail enclosures which suit a variety of applications as standard, as well as offering the option to customise the product to meet customer specific demands. A two option approach has been developed which gives design engineers the possibility to differentiate their product for both low and medium volumes, with excellent value to cost ratio, and without the need to invest in expensive tooling and processes.

The first of these options is aimed at low volume projects with typical annual quantities from one to three thousand pieces. Using a combination of high tech multiple tools, multiple axis CNC machines as well as low cost high quality laser and full colour digital printing processes, Hitaltech are able to offer a customised DIN rail mounting enclosures at exceptional value for money.

The second option is aimed at medium volumes with typical annual quantities from three thousand pieces. Using a multiple slide, flexible tooling approach, Hitaltech’s partner Italtronic have developed a range of mould tools that can be adapted by the inclusion of relatively low cost custom mould tool inserts to produce a finished custom DIN Rail mounting enclosure. This customised housing is produced direct from the injection moulding process therefore eliminating the need for additional machining.

This two option concept has recently been fully utilised by design engineers at Schneider Electric in the development of a new Remote Terminal Unit called the Talus T4e.

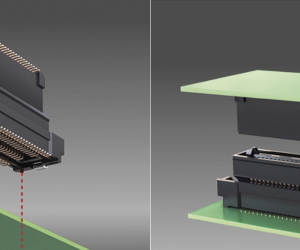

Used in water and waste water treatment sites, environmental monitoring systems, abstraction points and booster pumping stations, the Talus T4e is housed in Hitaltech’s standard DIN rail and wall mountable enclosure the 12M Modulbox.

What Hitaltech Did

Whilst working with the engineers at Schneider Electric it became apparent that they required a DIN rail mounting enclosure to have large internal volume for components with openings for a large number of inputs and outputs, as well as having both wall and DIN rail mounting capability.

The projected annual quantities fell into the small to medium volume category and therefore the customer did not want to invest in custom mould tools. Schneider Electric ideally wanted to receive the electronic enclosure already customised to their requirements allowing them to eliminate the need to sub contract out any machining or printing to a third party.

Based on these requirements Hitaltech proposed the Modulbox ‘C’ version. This DIN Rail mounting enclosure boasts two high shoulders compared to the traditional two step Modulbox design and therefore has the advantage of increased internal volume, giving more room for components and air flow.

In the early production stages, the production quantities were to be relatively small and therefore the customer elected for the machining option with a view to changing to the custom mould tool insert option once the projected higher volumes were realised.

As well as requiring custom openings for components, the customer also required laser markings on the enclosure and a digitally printed transparent top panel. The resulting finished product is housed in a DIN Rail enclosure which looks aesthetically pleasing, as well as giving a distinct customised look which meets both functional and aesthetical requirements.